Modern Factory

Dust-free welding workshop guarantees reliability and cleanness of the lights. The standardized die-casting workshop, CNC workshop, and painting workshop enable the lights to stand the test of time.

6000㎡

Factory Area

4M

Units Made Annually

15+

Export Markets

2003

In business Since 2003

Manufacturing Process

100% owned and operated production base provides reliable large-scale manufacturing.

Hardware Production

After a careful preparation of raw materials, we produce lighting hardware in a semi-automatic way. Our professional equipment produces hardware of high quality and durability.

- Laser marking

- Assembly of heat diffusers

- Welding of the light source

- Application of thermal grease

Product Assembly

With the help of clear product structure and rational design, our assemblies become efficient and precise. We offer robust lamps that meet the market demand.

Installation of the lens

Assembly of the lamp shell

Fixing the inner and outer ring

Inserting the spring

Testing

Testing electrical parameters is an essential part of the production process, and our experienced inspectors implement the principle of 100% good quality to provide you with safe lighting.

Aging test

Color temperature test

Performance Inspection

Heat dissipation test

Inspection & Packaging

We carry out a thorough inspection of all aspects of the finished product before shipping, and then pack it tightly to prevent damage to the fixture in transit.

Light Body Cleaning

Labeling

Supplying Instruction Manual

Quality Assurance

committed to achieving a 100% product test pass rate before shipment. Further products have also passed CCC and CE certifications. level 2 sampling and testing standards

Material Inspection

WEIKANG places special emphasis on the quality management of raw materials, as all incoming materials must undergo rigorous quality testing to ensure smooth production and subsequent processing.

We use important testing equipment to conduct various tests on incoming materials, such as salt spray tests, temperature tests and electronic tests.

Fabrication Inspection

During the production process, we conduct no less than three-stage inspections, namely inspection of the manufacturing process, inspection of the first finished product, and random inspection of the product.

Our quality inspectors check that each process complies with SOPs based on BOM and the specification sheets, perform touring inspections on the floor, and record the inspection results on the form.

Finished Product Inspection

Final full inspection of the product is crucial and we insist 100% pass inspection before shipment.

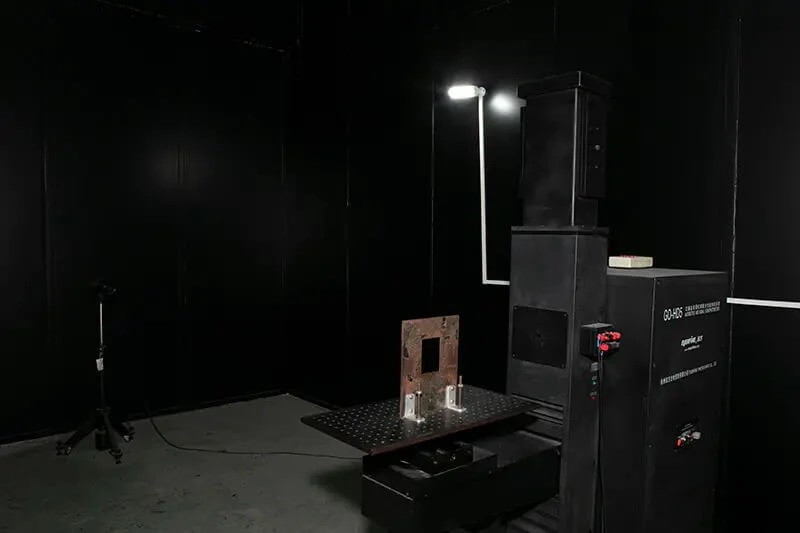

Our inspection department uses a photoelectric parameter tester with integrating sphere to check the luminous flux, color temperature and luminous efficiency of the light source, and then verifies the light brightness and light angle with a light distribution curve tester.

R&D

committed to achieving a 100% product test pass rate before shipment. Further products have also passed CCC and CE certifications. level 2 sampling and testing standards

Material Inspection

WEIKANG places special emphasis on the quality management of raw materials, as all incoming materials must undergo rigorous quality testing to ensure smooth production and subsequent processing.

We use important testing equipment to conduct various tests on incoming materials, such as salt spray tests, temperature tests and electronic tests.

Fabrication Inspection

During the production process, we conduct no less than three-stage inspections, namely inspection of the manufacturing process, inspection of the first finished product, and random inspection of the product.

Our quality inspectors check that each process complies with SOPs based on BOM and the specification sheets, perform touring inspections on the floor, and record the inspection results on the form.

Finished Product Inspection

Final full inspection of the product is crucial and we insist 100% pass inspection before shipment.

Our inspection department uses a photoelectric parameter tester with integrating sphere to check the luminous flux, color temperature and luminous efficiency of the light source, and then verifies the light brightness and light angle with a light distribution curve tester.